WO-2015087352

process for the synthesis of aryl sulfones

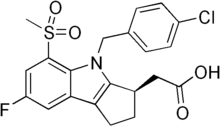

The present patent discloses a novel, efficient and transition-metal-free room temperature single step process for synthesis of aryl sulfones and substituted aryl sulfones starting from aryl substrates.

| Baburao Mhaske, Santosh;

Pandya, Virat |

| Novel and transition-metal-free,

room temperature, single step process for preparing aryl sulfones and

substituted aryl sulfones. Aryl sulfones are useful as intermediates in the synthesis of drugs eg rofecoxib and laropiprant; while substituted aryl sulfones possess anticancer and anti-HIV activities.  ROFECOXIB ROFECOXIB LAROPRIPRANT LAROPRIPRANTsee WO2014024212 (listing Santosh Baburao Mhaske as one of the inventors), claiming a similar one-pot synthesis of aryl phosphorous compounds. Also see Org Lett, Jul 2014, for an article, covering the theme of invention. WO2014024212 http://www.google.com/patents/WO2014024212A1?cl=en

Example 1: General Experimental Procedure for the Phosphorylation:

To a flame dried two-neck round-bottom flask containing CsF (5.50 equiv.) was added o-silyl aryl triflate (II) (1.00 equiv.) in acetonitrile, followed by addition of phosphorous compound of formula (III) (4.00 equiv.) in acetonitrile under argon atmosphere. The reaction mixture was stirred at room temperature and the progress was monitored by TLC. After completion of the reaction, acetonitrile was removed on rotary evaporator and the crude product was dried under high vacuum and purified by flash silica gel column using a gradient of ethyl acetate-petroleum ether to afford corresponding aryl-phosphorous compounds of formula (I) in good to excellent yields.

Example 2: Synthesis of diethyl phenylphosphonate (1)

To a stirred solution of CsF (Cesium Fluoride, 1.4 g, 9.22 mmol) in anhydrous acetonitrile (5 mL) was consecutively added o-trimethylsilyl phenyl triflate (500 mg, 1.67 mmol) and triethyl phosphite (1.12 g, 6.71 mmol). Reaction mixture was allowed to stir at room temperature (30 °C) for 20 hrs. The reaction mixture was concentrated and directly loaded on silica gel column and purified by using solvent gradient of Pet. EthenEthyl Acetate (1 : 1) to yield a colourless liquid phosphonate 1 (345 mg, 96%).

Reaction Time: 20 h, Rf. 0.4 (1 : 1 EtOAc:Pet. Ether); Thick oil; 345 mg, 96 %; Ή NMR (400 MHz, CDC13, TMS) δ 7.88-7.77 (m, 2H), 7.60-7.52 (m, 1H), 7.51 -7.43 (m, 2H), 4.22-4.02 (m, 4H), 1.33 (t, J= 7.2 Hz, 6H); 13C NMR (100 MHz, CDC13, TMS) δ 132.3 (d, J= 2.3 Hz), 131.7 (d, J= 10.0 Hz), 128.4 (d, J = 14.6 Hz), 128.3 (d, J = 188.0 Hz), 62.0 (d, J= 5.4 Hz), 16.3 (d, J = 6.2 Hz); 31P NMR (162 MHz, CDC13) δ 18.8; Mass (M+Na)+ 237; Known compound, Lit. M. Kalek, A. Ziadi, J. Stawinski, Org. Lett. 2008, 10, 4637. Example 3: Synthesis of dimethyl phenylphosphonate (2)

To a stirred solution of CsF (112 mg, 0.74 mmol) in anhydrous acetonitrile was consecutively added o-trimethylsilyl phenyl triflate (40 mg, 0.13 mmol) and trimethyl phosphite (67 mg, 0.53 mmol). Reaction mixture was allowed to stir at room temperature (30 °C) for 16 hrs. The reaction mixture was concentrated and directly loaded on silica gel column and purified by using solvent gradient of Pet. EthenEthyl Acetate (1 : 1) to yield a colourless liquid phosphonate 2 (22 mg, 90%).

Reaction Time: 16 h; Rf. 0.4 (1 :1 EtOAc:Pet. Ether); Thick oil; 22.0 mg, 90%; Ή NMR (500 MHz, CDC13, TMS) δ 7.80 (dd, J = 8.2, 13.4 Hz, 2H), 7.60-7.55 (m, 1H), 7.51-7.46 (m, 2H), 3.78 (s, 3H), 3.76 (s, 3H); 1 C NMR (125 MHz, CDC13, TMS) δ 132.6 (d, J= 2.9 Hz), 131.8 (d, J = 9.5 Hz), 128.5 (d, J = 15.3 Hz), 126.9 (d, J = 188.8), 52.6 (d, J = 5.7 Hz); 3,P NMR (162 MHz, CDCI3) δ 21.7; Mass (M + Na)+ 209; Known compound, Lit. M. Kalek, A. Ziadi, J. Stawinski, Org. Lett. 2008, 10, 4637.

Example 4: Dibutyl phenylphosphonate (3)

Example 5: Diethyl 2,5-dimethylphenylphosphonate (4):

3,6-dimethyl-2-(trimethylsilyl)phenyl trifluoromethanesulfonate (25mg, 0.076 mmol), Cesium Fluoride (64 mg, 0.421 mmol), Triethtyl phosphite (50 mg, 0.306 mmol), Acetonitrile (1 ml): Reaction Time: 35 h; Rf. 0.3 (1 :4 EtOAc:Pet Ether); Thick oil; 16.1 mg, 87 % ; Ή NMR (400 MHz, CDC13, TMS) δ 7.75 (d, J = 14.8, 1 H), 7.23 (d, J = 7.8 Hz, 1 H), 7.17-7.10 (m, 1H), 4.21-4.00 (m, 4H), 2.52 (s, 3H), 2.34 (s, 3H), 1.33 (t, J = 7.3 Hz, 6H); 13C NMR (100 MHz, CDCI3, TMS) 8 138.5 (d, J = 10.0 Hz), 134.9 (d, J = 14.6 Hz), 134.5 (d, J = 10.8 Hz), 133.2, 131.1 (d, 7 = 15.4 Hz), 126.3 (d, J = 182.7 Hz), 61.8 (d, J = 5.4 Hz), 20.7, 20.6, 16.3 (d, = 6.2 Hz); 31P NMR (162 MHz, CDC13) 6 20.0; Mass (M + Na)+ 265; Known Compound, Lit. S. Branion, V. Benin, Synth.Commun. 2006, 36, 2121.

Example 6: Diethyl 3-methoxyphenylphosphonate (5):

I .33 (t, J = 7.1 Hz, 6H); 13C NMR (100 MHz, CDC13, TMS) δ 159.4 (d, J= 18.5 Hz), 129.7 (d, J = 17.7 Hz), 129.6 (d, J= 187.3 Hz), 124.0 (d, J = 9.3 Hz), 1 18.8 (d, 7= 3.1 Hz), 1 16.4 (d, J =

I I .6 Hz), 62.2 (d, J = 5.4 Hz), 55.41, 16.3 (d, J = 6.2 Hz); 31P NMR (162 MHz, CDC13) δ 18.7; Mass (M + Na)+ 267; Known Compound, Lit. G. Yang, C. Shen, L. Zhang, W. Zhang. Tetrahedron Lett. 2011, 52, 5032.

Example 7: Diethyl benzo[d] [l,3]dioxol-5-ylphosph0nate (6):

6-(trimethylsilyl)benzo[d][l,3]dioxol-5-yl trifluoromethanesulfonate (25 mg, 0.073 mmol), Cesium Fluoride (61 mg, 0.402 mmol), Triethtyl phosphite (48 mg, 0.292 mmol), Acetonitrile (1 ml): Reaction Time: 16 h; Rf. 0.3 (2:3 EtOAc:Pet Ether); Thick oil; 16.0 mg, 85 %; Ή NMR (500 MHz, CDCI3, TMS) δ 7.38 (dd, J = 7.9, 14.0 Hz, 1H), 7.20 (d, J = 12.8 Hz, 1H), 6.88 (dd, J = 3.4, 7.6 Hz, 1H), 6.03 (s, 2H), 4.17-4.01 (m, 4H), 1.32 (t, J = 7.0 Hz, 6H); , C NMR (100 MHz, CDC13) TMS) 5151.2 (d, J = 2.9 Hz), 147.8 (d, J= 22.9 Hz), 127.4 ( d, J= 11.4 Hz), 121.3 (d,J= 193.6 Hz), 111.2 (d,/= 12.4Hz), 108.6 (d,J= 18.1 Hz), 101.5, 62.0 (d,J=5.7 Hz), 16.3 (d, J= 6.7 Hz); 3IP NMR (162 MHz, CDC13) δ 19.0 ; Mass (M + Na)+ 281; Known Compound, Lit. G. Yang, C. Shen, L. Zhang, W. Zhang. Tetrahedron Lett.2011, 52, 5032. Example 8: Diethyl 3,4-difluorophenylphosphonate (7):

4,5-difluoro-2-(trimethylsilyl)phenyl trifluoromethanesulfonate (25 mg, 0.078 mmol), Cesium Fluoride (62 mg, 0.411 mmol), Triethtyl phosphite (50 mg, 0.299 mmol), Acetonitrile (1 ml): Reaction Time 4 h; Rf: 0.5 (2:3 EtOAc:Pet Ether); Thick oil; 14.6 mg, 78 %; Ή NMR (500 MHz, CDC13> TMS) δ 7.67-7.55 (m, 2H), 7.31-7.23 (m, 1H), 4.21-4.05 (m, 4H), 1.34 (t, J= 7.0 Hz, 6H); 13C NMR (125 MHz, CDC13, TMS) 6153.1 (ddd, J= 3.8, 12.4, 255.6 Hz), 150.2 (ddd, J= 13.4, 22.9, 252.7 Hz), 128.8 (ddd, J= 3.8, 6.7, 10.5 Hz) 125.9 (dt, J= 3.8, 192.7 Hz), 121.1 (dd,J= 11.4, 18.1 Hz), 117.9 (t,J= 18.1 Hz), 62.4 (d, J= 4.8 Hz), 16.2 (d, J= 5.7 Hz) 3,P NMR (162 MHz, CDC13) δ 15.8 (apparent t, JPF = 6.1 Hz); HRMS-ESI (m/z) calcd (CioH,3F203P + H)+: 251.0643 found: 251.0643.

Example 9: Dimethyl 3,4-difluorophenylphosphonate (8): O

F^^P(OMe)2

4,5-difluoro-2-(trimethylsilyl)phenyl trifluoromethanesulfonate (25 mg, 0.074 mmol), Cesium Fluoride (62 mg, 0.411 mmol), Trimethtyl phosphite (37 mg, 0.299 mmol), Acetonitrile (1 ml): Reaction Time: 4 h; Rf.0.4 (1:3 EtOAc:Pet Ether); Thick oil; 11.8 mg, 71 %; Ή NMR (400 MHz, CDC13, TMS) S 7.67-7.53 (m, 2H), 7.34-7.24 (m, 1H), 3.79 (s, 3H), 3.77 (s, 3H); 13C NMR (100 MHz, CDC13, TMS) δ 153.3 (ddd, J = 3.9, 12.3, 256.6 Hz), 150.3 (ddd, J= 12.3, 22.4, 252.0 Hz), 129.0 (ddd, J= 3.9, 6.9, 10.8 Hz), 124.2 (dt,J=3.9, 193.4 Hz), 121.3 (dd,J = 11.6, /= 18.5 Hz), 118.0 (t, J= 17.7 Hz), 52,9 (d, J= 6.2 Hz);31P NMR (162 MHz, CDC13) δ 18.6 (d, JpF = 7.5 Hz); HRMS-ESI (m/z) calcd (C8H9F203P + H)+: 223.0330 found: 223.0335.

Example 10: Diethyl naphthalen-2-ylphosphonate (9):

Example 11: Synthesis of ethyl diphenylphosphinate (10) To a stirred solution of CsF (70 mg, 0.46 mmol) in anhydrous acetonitrile (1 mL) was consecutively added o-trimethylsilyl phenyl inflate (25 mg, 0.08 mmol) and diethyl phenyl phosphonite (66 mg, 0.33 mmol). Reaction mixture was allowed to stir at room temperature (30 °C) for 24 hrs. The reaction mixture was concentrated and directly loaded on silica gel column and purified by using solvent gradient of Pet. EthenEthyl Acetate (1 : 1) to yield a colourless liquid phosphinate (15.7 mg, 76%).

Reaction Time: 24 h; Rf: 0.3 (1 : 1 EtOAc:Pet Ether); Thick oil; 15.7 mg, 76 %; Ή NMR (400

MHz, CDC13) TMS) δ 7.87-7.77 (m, 4H), 7.55-7.48 (m, 2H), 7.47-7.39 (m, 4H), 4.1 1 (apparent quint, J = 7.1 Hz, 2H), 1.37 (t, J = 7.1 Hz, 3H); 13C NMR ( 100 MHz, CDC13, TMS) 5 132.0 (d, J = 2.1 Hz), 131.6 (d, J = 136.4 Hz), 131.5 (d, J = 10.1 Hz), 128.4 (d, J = 13.1 Hz ), 61.1 (d, J = 5.4 Hz), 16.4 (d, J = 6.2 Hz); 31 P NMR (162 MHz, CDC13) 8 31.3; HRMS-ESI (m/z) calcd (CMH,502P + H)+ : 247.0882 found: 247.0886; Known compound, Lit. C. Huang, X. Tang, H. Fu, Y. Jiang, Y. Zhao, J. Org. Chem. 2006, 71, 5020.

Example 12: Ethyl (2,5-dimethylphenyl)(phenyl)phosphinate (11):

3,6-dimethyl-2-(trimethylsilyl)phenyl trifluoromethanesulfonate (25 mg, 0.077 mmol), Cesium Fluoride (64 mg, 0.421 mmol), Diethyl phenylphosphonite (60 mg, 0.306 mmol), Acetonitrile (1 ml): Reaction Time: 32 h; Rf. 0.4 (1 : 1 EtOAc:Pet Ether); Thick oil; 13.0 mg, 62 %; Ή NMR (400 MHz, CDC13, TMS) δ 7.81 -7.70 (m, 3H), 7.52-7.40 (m, 3H), 7.23 (d, J = 7.8 Hz, 1H), 7.12-7.05 (m, 1H), 4.11 (apparent quint, J = 7.0 Hz, 2H), 2.36 (s, 3H), 2.33 (s, 3H), 1.38 (t, J = 7.0 Hz, 3H); ,3C NMR (100 MHz, CDC13, TMS) 5 138.6 (d, J = 10.8 Hz), 135.0 (d, J = 12.3 Hz), 133.9 (d, J = 9.3 Hz), 132.5 (d, J = 124.1 Hz), 128.4 (d, J = 13.4 Hz ), 131.7, 131.5 (d, J = 7.7 Hz), 131.4, 131.3, 129.0 (d, J = 133.3 Hz), 128.4 (d, J = 13.1Hz), 60.7 (d, J= 5.4 Hz), 20.9, 20.7 (d, J = 3.9 Hz), 16.4 (d, J = 6.9 Hz); 3 IP NMR (162 MHz, CDC13,) δ 32.2; HRMS-ESI (m/z) calcd (β,6Η,9θ2Ρ + H)+ : 275.1 195 found: 275.1 193.

Example 13: (2,5-dimethylphenyl)diphenylphosphine oxide (12)

To a stirred solution of CsF (63 mg, 0.42 mmol) in anhydrous acetonitrile 1 mL was consecutively added 2,5 dimethyl -(o-trimethyl silyl)phenyl triflate (25 mg, 0.077 mmol) and ethoxydiphenylphosphine (60 mg, 0.31 mmol). Reaction mixture was allowed to stir at room temperature (30 °C) for 30 hrs. The reaction mixture' was concentrated and directly loaded on silica gel column and purified by using solvent gradient of Pet. EthenEthyl Acetate (1 : 1) to yield a white solid phosphine oxide (19 mg, 81%).

Reaction Time: 30 h; Rf: 0.3 (1 : 1 EtOAc:Pet Ether); White Solid; mp 157-159 °C; 19.0 mg, 81 %; 1 H NMR (400 MHz, GDC13, TMS) δ 7.75-7.60 (m, 4H), 7.59-7.52 (m, 2H), 7.51-7.43 (m, 4H), 7.26-7.20 (m, 1H), 7.19-7.13 (m, 1H), 6.88 (d, J = 14.4 Hz, 1H), 2.37 (s, 3H), 2.21 (s, 3H); 13C NMR ( 100 MHz, CDCI3, TMS) 5 140.0 (d, J = 7.7 Hz), 134.7 (d, J = 13.1 Hz), 133.9 (d, J = 12.3 Hz), 132.9 (d, J = 103.3 Hz), 132.8 (d, J = 2.3 Hz), 13Ί .9 (d, J = 10.0 Hz), 131.8, 131.7 (d, J = 3.1 Hz), 130.4(d, J= 103.3 Hz), .128.5 (d, J = 11.6 Hz), 21.2 (d, J = 4.6 Hz), 21.0; 31P NMR ( 162 MHz, CDCI3) δ 31.7; HRMS-ESI (m/z) calcd (C20H19OP + H)+ : 307.1246 found: 307.1244. Example 14: Synthesis of (3-methoxyphenyl)diphenylphosphine oxide (13)

To a stirred solution of CsF (64 mg, 0.42 mmol) in anhydrous acetonitrile was consecutively added 2-methoxy (o-trimethyl silyl) phenyl triflate (25 mg, 0.077 mmol) and ethoxydiphenylphosphine (61 mg, 0.31 mmol). Reaction mixture was allowed to stir at room temperature (30 °C) for 20 hrs. The reaction mixture was concentrated and directly loaded on silica gel column and purified by using solvent gradient of Pet. EthenEthyl Acetate (1 : 1) to yield a white sticky solid phosphine oxide (16 mg, 68%).

Reaction Time: 20 h; Rf. 0.3 (1 : 1 EtOAc:Pet Ether); Thick oil; 16.0 mg, 68 %; Ή NMR (400 MHz, CDC13, TMS) δ 7.71-7.63 (m, 4H), 7.59-7.52 (m, 2H), 7.50-7.43 (m, 4H), 7.40-7.29 (m, 2H), 7.18-7.05 (m, 2H), 3.80 (s, 3H); 13C NMR (100 MHz, CDC13, TMS) δ 159.6 (d, / = 15.4 Hz), 133.8 (d, 7 = 103.3 Hz), 132.4 (d, J = 104.0 Hz), 132.1 (d, J = 10.0 Hz), 131.9 (d, J = 3.1 Hz), 129.6 (d, J= 14.6 Hz), 128.5 (d, J= 12.3 Hz), 124.4 (d, J= 10.0 Hz), 1 18.2 (d, J= 3.1 Hz), 1 16.7 (d, J = 10.8 Hz), 55.4; 31P NMR (162 MHz, CDC13) δ 29.5; HRMS-ESI (m/z) calcd (C19Hi702P + H)+ : 309.1039 found: 309.1034; Known compound, Lit. X. Zhang, H. Liu, X. Hu, G. Tang, J. Zhu, Y. Zhao, Org. Lett. 2011, 13, 3478.

Example 15: Triphenylphosphine oxide (14):

2-(trimethylsilyl)phenyl trifluoromethanesulfonate (25 mg, 0.083 mmol), Cesium Fluoride (70 mg, 0.461 mmol), Ethoxydiphenylphosphane (78 mg, 0.33 mmol), Acetonitrile (1 ml): Reaction Time: 16 h; Rf: 0.3 (1 :3 EtOAc:Pet Ether); White Solid; 17.5 mg, 75 %; Ή NMR (400 MHz, CDC13, TMS) δ 7.74-7.63 (m, 6H), 7.59-7.51 (m, 3H), 7.50-7.40 (m, 6H);13C NMR (100 MHz, CDCI3, TMS) δ 132.5 (d, J = 104.0 Hz), 132.1 (d, J = 10.0 Hz), 131.9 (d, J= 2.3 Hz); 128.5 (d, J = 12.4 Hz); 31P NMR (162 MHz, CDC13) δ 29.2; Mass (M + Na)+ 301; Known Compound, Lit. K. Prokop, D. Goldberg, J. Am. Chem. Soc. 2012, 134, 8014.

Example 16: Naphthalen-2-yldiphenylphosphine oxide (15):

1. Raw materials are commercially available and inexpensive

2. One pot process

3. Room temperature process

4. The process is useful in generating chiral phosphine oxides under mild conditions that can serve as precursors to obtain novel aryl-phosphine ligands useful in organic synthesis. .

|